About us

Speedibake first opened in 1984, with bakery sites located at Northampton and Wakefield. It is now a single site operation in Bradford where our passion lies in crafting delicious baked goods. All finished products are distributed frozen to our various sectors including retail, foodservice, wholesalers, contract catering, and export. Since we opened the bakery doors, we’ve specialised in manufacturing muffins, mince pies, plain baguettes, garlic baguettes, and garlic slices alongside providing tailored bakery solutions for our delighted customers.

Situated proudly in Yorkshire, our factory sprawls across 17,500 thousand square feet, where we pour our hearts, passion and extensive bakery knowledge into every product. With a keen eye on market trends, we’ve heavily invested in our product team and state of the art machinery, to guarantee that our offerings stay modern, on trend, appealing, and always delicious. We are proud of our dedicated 350 plus bakery staff, many boasting over 15 years’ service with us, they are the backbone of our bakery success and represent 25 different nationalities. We take pride in our remarkable diversity.

We’re proud to be a part of Associated British Foods (ABF), a Associated British Foods is a highly diversified group, with a range of food and ingredients businesses as well as our retail brand, Primark. We are united in our purpose: to provide safe, nutritious and affordable food, and clothing that is great value for money. ABF employs over 133,000 people with a revenue of £19.8bn and operates in 55 countries across Europe, southern Africa, the Americas, Asia and Australia.

Our vision is simple, it’s to build a sustainably profitable bakery business.

Our History

1983

Garry Weston identified a niche opportunity in the UK bakery market based on what he had seen in the USA. His idea was to manufacture authentic French breads and part bake them. These would then be frozen, so that they could be packed in bulk and then sold to the major retailers, who would finish off the bake in-store.

1984

Speedibake was established at the Allied Bakeries site in Northampton, producing baguettes, croissants, rolls and pastries.

1985

Further production lines are installed, enabling a range of garlic products to be manufactured. To meet all this additional demand, the cold-storage facility is also extended, with capacity increased to 1870 pallets.

1988

Speedibake’s success continues and it opens up a second site in Wakefield, at a cost of £10m, with cold-storage capacity of 2080 pallet spaces to meet the ever-growing demand. This enables the business to further expand its product category portfolio, with Wakefield producing doughnuts, mince pies and fruit pies.

1992

Additional doughnut capacity is added to the Wakefield site with the installation of a new production line.

1993

To meet growth demands within the market, Speedibake opens up a third site, repurposing the Allied Bakeries Bradford site at a cost of £13m, which includes a purpose built 3000 pallet cold-storage facility.

1994

Speedibake start supplying cake muffins from its Bradford site, which now also produces mince pies, fruit pies and custard pies, following the relocation of that production line from Wakefield. This move enables even more doughnut capacity to be added to the Wakefield operation, with the installation of a third production line.

1996

Speedibake invests a further of £12m, for both sites, which includes a second cold-storage facility at Bradford which has a capacity to hold over 5000 pallets of frozen finished goods. This cements the businesses position as a leading manufacturing of frozen foods in its chosen markets of cake muffins, doughnuts, speciality breads, sweet pies and tarts.

1998

Further muffin capacity is added to the Bradford site, which also including a robot packaging line.

2001

Unfortunately, Speedibake Northampton, the original site closes at the end of the year, with all its production lines relocated between Wakefield and Bradford.

2007

A new, large muffin line is installed at the Bradford site, which is commissioned the following year.

2011

Garlic slice capacity is significantly increased at the Bradford site, which includes a state-of-the-art robot picking being installed to hand this increased output.

2015

The business invests £5.5m in a new state-of-the-art muffin line, that has significantly enhanced functionality to inject, decorate and top products. This gives Speedibake addition capacity and the capability to manufacture cakes muffins from value to speciality.

2017

Speedibake makes further investment, spending £12m on a new, ultra-modern doughnut production line that is the largest in Europe, installed in its Wakefield site, ready for commissioning before the end of the year.

2019

Cold store 2 decommissioned at Bradford site.

2020

1st February, a catastrophic fire breaks out at the Wakefield site, unfortunately leading to its permanent closure.

2020

23rd March, The UK Government announces a nationwide lockdown to prevent the spread of Covid-19.

2020

Speedibake becomes a single site business making cake muffins, garlic breads, speciality breads and mince pies operating from its Bradford site.

2022

The business unveils plans to invest up to £5m on its plant, equipment and facilities over a 30-month period, with a strong focus on delivering sustainably reliable production.

2023

Speedibake announces an £8m investment in a new production line, which will be commissioned in September that will create a new premium sourdough business. Working in close partnership with AB Mauri, Speedibake will become the sole UK manufacturer of Scrocchiarella, a premium, high quality ‘pinsa type’ Italian flatbread.

Our Culture, our people

Speedibake has drawn on it’s history and geographical location to organically grow a diverse culture that encourages education and awareness of our varying differences. Through our challenges and growth, we are proud of our history and determined to succeed.

Our friendly, fun-loving approach is backed by a challenging nature that strives for quality and exceeding standards – we just do this with a smile on our face. This is all because our people are the most important part of our business and, ensuring Speedibake feels like home for all our employees, is crucial to our success.

More importantly, our colleagues’ health, safety and wellbeing is important to us – we want everyone to go home after a day’s work as healthy and happy as when they arrived. Our positive health and safety culture is one where people work together to make safety part of everything we do. We promote and support our colleagues’ health and wellbeing so that people have the physical and mental capability to be satisfied in their work and contribute to the success of the business.

Alongside that is our belief in developing our people, be that through our popular Apprenticeship scheme, our internal GROW (Getting you Ready for Opportunities at Work) programme, our links with local Schools and Colleges to build awareness of food manufacturing or simply the hours of training we make available for our teams.

Our values

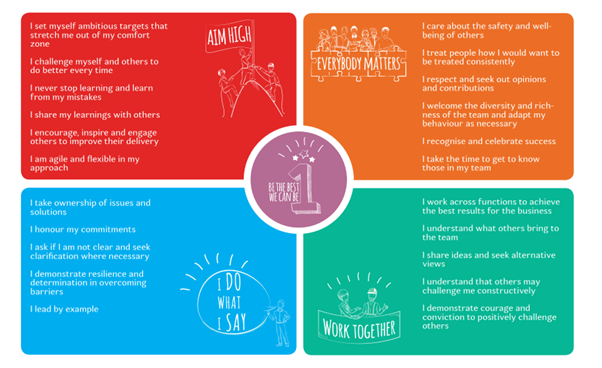

At Speedibake we like to remove complication and simply believe that there is only one Value – Be the best we can be. This value is underpinned by our 4 most important behaviours.

We promote these behaviours into everything we do a through our recognition scheme, Raise the Bar, we ensure we recognise and give back to those who excel in the promoting of these behaviours.

We All Belong

We’re working hard at Speedibake to ensure that everybody feels they belong; our vision is for everyone to feel free to bring their whole self to work and to feel proud that our workplace reflects the community we live in.

Inclusion and diversity are increasingly central to our decision-making across the business, and we have multiple streams that support this through our inclusion in the Allied Milling and Baking I&D forum and the Grocery Group I&D forum. These forums are designed to share experiences and ideas throughout the different business to create and inclusive business.

Watch this film to hear some of our colleagues talk about their experience of working at Speedibake and our sister companies Allied Bakeries and Allied Mills.